Thermoplastics show up in more places than many people realize. From seats on public buses to covers on heavy-duty equipment, and especially in construction and healthcare, this material has quietly become a top choice for manufacturers ready to rethink how things are made. SAY Plastics is a thermoplastics manufacturing company that makes better designs possible, using smart molding processes to update or improve traditional metal and FRP parts.

Everyday parts need to handle regular use, deal with changing weather, and stay affordable. Thermoplastics check all those boxes every time. Whether it’s a truck panel that shields components or a lightweight cover for equipment, these products take hits without adding extra weight or cost. Here’s a look at how SAY Plastics does this by building custom parts, backing a range of industries, and what makes them unique when it comes to both materials and process.

Understanding Thermoplastics and How They’re Made

Thermoplastics are different from other materials because they get soft when heated and harden as they cool. That setup allows them to be reshaped more than once, and they keep their quality each time. This flexibility is a big reason manufacturers pick them instead of metals or fiberglass-reinforced plastic.

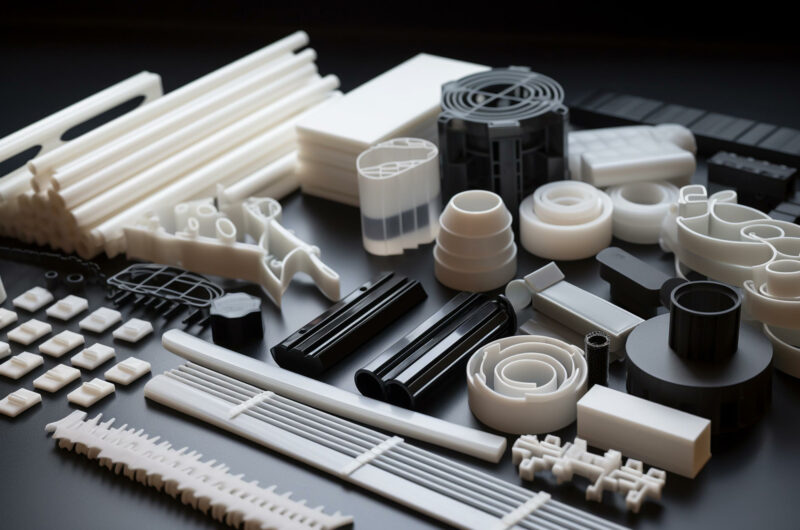

There are three processes to know about. Vacuum forming means pulling a plastic sheet over a mold using air pressure. It’s a simple pick for big parts that don’t need fine details. Pressure forming adds more force, making sharper edges and cleaner lines, making it better for visible parts. CNC trimming comes next, where machines cut and finish those plastic sheets into exact shapes, ready for use.

A lot of people choose thermoforming because it moves fast from an idea to a real part. The tools for the first mold get made quicker and easier than what’s needed for injection molding or metal stamping. So projects shift from prototype to full runs with fewer stalls.

At Garnett Component Sales, clients get help picking the right thermoforming process for their projects, along with a review of the best material for the job. This support ensures every part comes together as efficiently as possible.

SAY Plastics’ Step-by-Step Process

Work at SAY Plastics begins before a single piece of plastic is formed. Early planning matters most and customers are kept in the loop with every step. Much of the time, the process starts by reviewing parts built from other materials. The goal is to redesign these for thermoformed plastic, making them lighter and easier to use.

Collaboration is front and center, and not just among engineers. Tool design, scheduling production, and checking quality all happen together. SAY Plastics uses 5-axis CNC machines, which shape molds and trim parts with a lot of accuracy. These machines can reach around odd angles, cutting parts that might be tricky for other tools, and often finish pieces faster, which keeps the production moving.

A big piece of what sets SAY Plastics apart is the way they handle tooling. Instead of traditional heavy steel tools that take a long time to make, tailored tooling uses simpler materials and speeds up changes. This reduces downtime if the design shifts, which often saves both time and scrap.

Clients working with Garnett Component Sales benefit from this flexible tooling approach. The agency supports projects with up-to-date production support and on-site technical advice, making sure the process is smooth right from the earliest discussions.

Real-World Uses Across Different Industries

Thermoplastic parts from SAY Plastics can be found in all kinds of places. Think interiors for buses or trains, panels for trucks, or sturdy covers for controls. Exterior pieces, like wheel guards or bumpers, stand up to bumps but don’t bend out of shape.

In fields like construction or material handling, the perks go even further. Equipment panels, shields, or special packaging made from thermoformed plastic hold up well against dirt and damp work sites. Medical equipment covers made from these plastics help keep surfaces clean since they resist stains, don’t rust, and handle scrubbing without getting damaged.

As the season shifts into fall, companies often need to update how parts get stored or shipped. Returnable packaging with thermoplastics lasts through long trips, resists moisture, and handles the strain of heavy contents. This makes them an easy choice for busy months when schedules ramp up.

Some of these solutions are used in:

– Passenger and driver safety panels in transportation vehicles

– Impact-resistant housing for sensitive controls in construction equipment

– Lightweight, easy-to-clean shells for high-use medical gear

– Moisture-resistant containers for equipment parts and material shipments

Tough Materials That Handle a Lot

Thermoplastics work well for more than just being lightweight. Many built-in benefits come standard. Some types have UV protection to keep from breaking down when left in the sun. Others were picked to handle impacts, making them perfect for parts that might be dropped or bumped during regular use.

There are strict rules for fire safety in some industries, especially where people are involved. Materials used by SAY Plastics can meet UL94V0 and FST standards, which are often required for parts in buses or trains. These tough plastics slow down flames and help keep people safe.

In rough environments, these parts hold out longer because they don’t corrode or split the way metal or untreated plastics can. Fewer replacements and fewer repairs keep everything running, which matters when the work never really stops for seasonal changes.

Fixing Problems with Custom Solutions

Thermoplastic shielding plays a big part in protecting equipment and parts. Bus interiors, which see heavy foot traffic every day, need covers that can take scrapes and keep looking new. Machines that move through shipping and loading zones benefit from shields that prevent knocks from turning into expensive damage.

When it comes to the line, good part fit cuts down on mistakes and keeps scrap out of the bins. Little tweaks, made early in the design process, mean less rework later. The clasSAY global group keeps in touch with field teams, so fixes in the design stage really do work on the floor.

This approach is important once things get busy in the fall and there’s less room for slowdowns. Being able to swap out thermoformed parts quickly, without backing up the supply chain, is a practical solution for factories facing tight deadlines.

Here are ways these custom solutions help:

– Custom covers keep service parts working longer, reducing maintenance stops

– Shields protect from scuffing, scratching, and impacts that can shorten a part’s life

– Smart design reduces rework and keeps assemblies fitting right the first time

Smart Design for All Seasons

Thermoforming isn’t just about switching one part for another. With SAY Plastics, it’s a chance to build smarter parts that stick around longer and cut down on replacement costs. Planning ahead with engineering and collaboration from the start means parts are made faster and usually fit right the first time.

As fall rolls in and manufacturers start setting up for busy runs, having tough covers, spare parts, and sturdy packaging is a smart way to keep everything on track. These aren’t just spare pieces—they’re a key part of keeping systems reliable through seasonal rushes.

If you need help sorting out which parts should move to thermoforming, or how to pick the best materials, make sure to work with partners who know the finishes, shapes, and certifications your industry needs. Thermoplastics can help your production line stay up and running, even when the schedule doesn’t leave much room for error.

Thermoformed plastic offers smart advantages when you’re facing design or durability challenges. It helps protect parts in tough conditions and keeps production schedules on track. It’s a strong fit for teams looking to simplify assemblies and stay flexible with part designs and finishes. At Garnett Component Sales, we work closely with manufacturers to rethink what’s possible—including projects related to CNC machining—so you can build with fewer delays and more confidence. Let’s talk about what’s next.